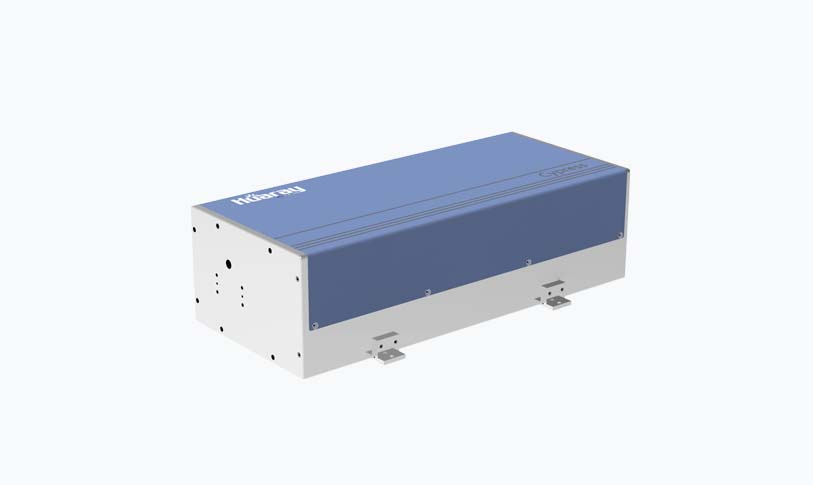

[150w co2 laser]Exploring the Versatility and Applications of 150W CO2 Lasers in Modern Industries

In the realm of cutting-edge technology, 150W CO2 lasers stand out as powerful tools that have revolutionized various industries. With their ability to emit a high level of energy, these lasers facilitate precise cutting and engraving, making them invaluable in manufacturing and design sectors. This article delves into the diverse applications of 150W CO2 lasers and their significance in today’s technology-driven world.

One of the primary applications of a 150W CO2 laser is in the field of materials processing. These lasers are adept at cutting through a variety of materials, including wood, acrylic, leather, and certain metals. The precision offered by these lasers ensures clean cuts, reducing the need for further finishing processes. Industries such as furniture design, signage creation, and automotive manufacturing have been able to enhance their efficiency and product quality thanks to the capabilities of 150W CO2 lasers.

Exploring the Versatility and Applications of 150W CO2 Lasers in Modern Industries

Exploring the Versatility and Applications of 150W CO2 Lasers in Modern Industries

In the realm of engraving, the 150W CO2 laser provides unmatched detail and clarity. It can be used to engrave intricate designs on surfaces, allowing for customization of products ranging from gifts to industrial components. The ability to engrave on various materials opens up creative possibilities for artists and designers, enabling them to transform ordinary objects into personalized masterpieces.

Moreover, these lasers are crucial in the textile industry. With their precise cutting capabilities, 150W CO2 lasers are used to create intricate patterns in fabrics, making them ideal for fashion design and upholstery. The speed of laser cutting reduces production time significantly, allowing businesses to respond quickly to market trends. This adaptability is increasingly important in a fast-paced, ever-changing retail environment.

Exploring the Versatility and Applications of 150W CO2 Lasers in Modern Industries

Another significant application of 150W CO2 lasers is in medical technology. These lasers are employed in surgical procedures, particularly in soft tissue surgeries, due to their ability to precisely cut tissue while minimizing damage to surrounding areas. The resulting less invasive procedures lead to quicker patient recovery times and reduced risk of infection, showcasing the life-saving potential of this technology.

As industries seek more sustainable solutions, 150W CO2 lasers are emerging as a greener alternative to traditional cutting and engraving methods. The efficiency of laser utilization means less waste generated during production. Additionally, these lasers consume less energy compared to other cutting technologies, contributing to a smaller carbon footprint. This aligns with the growing global focus on sustainability and environmental conservation.

The user-friendly interface of many 150W CO2 laser systems also makes them accessible to a broader range of users, from large corporations to small businesses and hobbyists. The proliferation of affordable laser engraving and cutting machines has democratized access to this technology, allowing smaller entities to take advantage of its benefits without the need for significant capital investment.

In conclusion, the 150W CO2 laser represents a versatile and powerful tool in modern manufacturing and design industries. With applications spanning from precision cutting and engraving to medical procedures and sustainable practices, it’s clear that the impact of this technology is far-reaching. As advancements continue to unfold, the potential of 150W CO2 lasers will likely expand even further, driving innovation and efficiency across sectors. Embracing this technology today means paving the way for a more precise, efficient, and sustainable future.tube fiber laser