[best co2 laser]Discovering the Best CO2 Laser: Your Ultimate Guide to Choosing the Ideal CO2 Laser for Engraving, Cutting, and More

When it comes to precision cutting and engraving, CO2 lasers are among the most effective tools available today. These versatile machines are widely used across various industries, including manufacturing, woodworking, acrylic crafting, textiles, and even medical applications. Choosing the best CO2 laser for your specific needs can be a daunting task due to the myriad of options on the market. This guide aims to illuminate your path to finding the ideal CO2 laser for your project requirements.

What is a CO2 Laser?

A CO2 laser is a type of gas laser that uses a mixture of carbon dioxide, nitrogen, helium, and hydrogen as the primary medium for generating laser light. The wavelength of the light produced, typically around 10.6 micrometers, makes it especially effective for cutting and engraving various materials, including wood, glass, acrylic, and fabric. It operates by focusing the laser beam onto the material’s surface, allowing for precision cutting and etching.

Essential Factors to Consider When Choosing the Best CO2 Laser

1. **Power Output**

The effectiveness of a CO2 laser largely depends on its power output, usually measured in watts. For general engraving, a power output of 30-60 watts is often sufficient. However, for cutting thicker materials, you may need a laser with a higher wattage, typically above 100 watts. Assess your project requirements to determine the necessary power level.

2. **Workspace Size**

Discovering the Best CO2 Laser: Your Ultimate Guide to Choosing the Ideal CO2 Laser for Engraving, Cutting, and More

Discovering the Best CO2 Laser: Your Ultimate Guide to Choosing the Ideal CO2 Laser for Engraving, Cutting, and More

The optimal size of your CO2 laser’s work area will depend on the nature of your projects. If you are primarily working with smaller items, a machine with a compact workspace may suffice. Conversely, for larger projects, such as signage or furniture, a machine with a spacious work area, typically ranging from 24″x12″ to 72″x36″, will be invaluable.

3. **Speed and Precision**

Laser engraving and cutting speed are crucial for increasing productivity. Look for a CO2 laser that allows you to adjust the speed settings according to the material and design complexity. Coupled with speed is precision; the laser’s optical system should ensure clean cuts and detailed engravings without excessive burning or fraying.

4. **Cooling System**

Cooling systems play a critical role in maintaining consistent laser performance. A CO2 laser can generate significant heat during operation, so a good cooling system—whether it is water-cooled or air-cooled—is essential to extend the life of the machine and ensure optimal functionality.

5. **Software Compatibility**

Discovering the Best CO2 Laser: Your Ultimate Guide to Choosing the Ideal CO2 Laser for Engraving, Cutting, and More

Most CO2 lasers come with proprietary software that allows you to create and manage designs. However, compatibility with popular design software like Adobe Illustrator, CorelDRAW, or AutoCAD can enhance your workflow and versatility. Evaluate what software options are available and whether they meet your project needs.

6. **Price and Warranty**

Budget is always a key consideration when investing in equipment. The price range for CO2 lasers can vary significantly, from entry-level models costing a few hundred dollars to high-end machines priced in the thousands. Be sure to factor in quality, features, and warranty options when making your decision. A reliable warranty can provide peace of mind and protection for your investment.

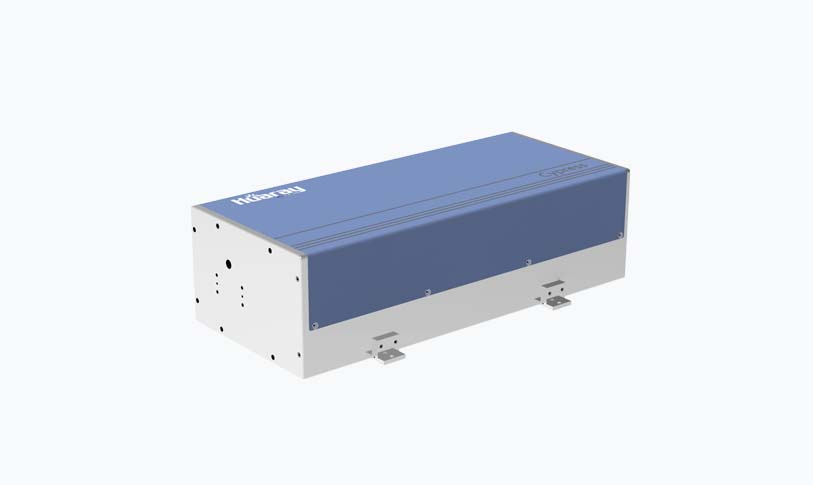

Popular CO2 Laser Models

**1. Epilog Laser Zing Series** The Epilog Zing series is known for its exceptional precision and speed, making it a top choice for small businesses and hobbyists. With a robust design and power options starting from 30 watts, it’s perfect for laser engraving and cutting diverse materials.

**2. Glowforge Pro** Ideal for hobbyists and small startups, the Glowforge Pro has made waves in the laser-cutting community with its user-friendly design and software. Its powerful laser can cut and engrave wood, leather, and acrylic seamlessly.

**3. Trotec Speedy Series** For commercial use, the Trotec Speedy series is a high-performance option, offering impressive speeds and precision. With various power options up to 120 watts, it’s suitable for industrial applications and mass production.

Conclusion

Finding the best CO2 laser depends on several factors, including application needs, workspace size, speed, and feature set. By carefully evaluating these aspects, you can select the perfect laser for your projects, whether for hobbyist purposes or professional applications. With the right CO2 laser in hand, the possibilities for creativity and innovation are virtually limitless.ezcad2 software